1. Overview

PCB (Printed Circuit Board) is the foundation of every electronic product.

It connects and supports electronic components while ensuring the circuit’s electrical functionality.

A well-designed PCB layout and routing not only guarantees reliable circuit performance, but also plays a key role in electromagnetic compatibility (EMC), anti-interference capability, and overall manufacturability.

2. Component Layout Guidelines

- Modular Design Group components by function. Keep related circuits close together. Separate analog and digital sections to reduce interference.

- Hole and Clearance Rules

- Keep all components at least 1.27 mm away from positioning or reference holes.

- Around mounting holes: ≥ 3.5 mm (M2.5) or ≥ 4 mm (M3) clearance.

- Component edges should be at least 5 mm from the PCB edge.

- Mechanical & Soldering Considerations

- Avoid placing vias beneath horizontal resistors, inductors, or electrolytic capacitors to prevent post-solder shorts.

- Maintain ≥ 2 mm spacing between metallic parts (e.g. shielding boxes) and traces or pads.

- Avoid vias on SMT pads to prevent solder paste loss and weak joints.

- Orientation & Appearance Consistency

- ICs should align in one direction; polarized components should share the same marking orientation (no more than two directions on one board).

- Silkscreen text and package alignment should remain consistent.

- Thermal Design

- Keep heat-generating components away from heat-sensitive parts.

- Distribute high-power devices evenly to avoid thermal concentration.

- Power & Connector Placement Place power connectors near board edges for easy wiring and soldering. Avoid locating power jacks between other connectors; ensure sufficient space for cable insertion and removal.

3. Routing and Electrical Design Rules

- Routing Area Limits No traces should be placed within 1 mm of the board edge or mounting holes.

- Trace Width and Clearance

- Power traces: ≥ 18 mil

- Signal traces: ≥ 12 mil

- CPU lines: ≥ 10 mil

- Trace spacing: ≥ 10 mil

- Via diameter: ≥ 30 mil

- Impedance and Signal Integrity Power and ground lines should radiate outward from a single source. Avoid routing signal loops; use 45° bends instead of sharp 90° corners to reduce EMI radiation.

4. Improving EMI and Noise Immunity

- Systems Requiring Special EMC Attention

- High-speed clock or bus systems.

- Circuits with large power switches, relays, or inductive loads.

- Mixed-signal designs involving weak analog signals or precision A/D converters.

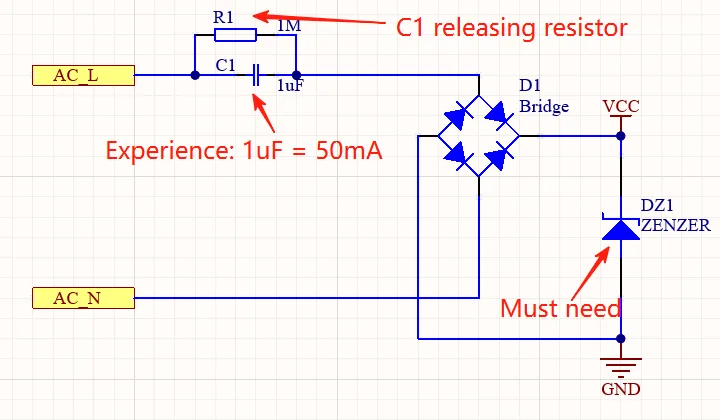

- Key EMC and Anti-Interference Techniques

- Lower Clock Frequency: Use the lowest feasible clock to reduce harmonic radiation.

- Signal Integrity: Keep traces short, minimize vias, and apply termination resistors for impedance matching.

- Crosstalk Reduction: Separate digital and analog signals by layer; maintain a continuous ground plane beneath signal traces.

- Power Filtering: Add decoupling capacitors (e.g. 0.1 µF + 1 µF) between power and ground near each IC.

- Ground Strategy: Use single-point connection between analog and digital grounds; ensure continuous low-impedance return paths.

- Shielding: Apply grounded metal shields to high-frequency or noise-sensitive areas when necessary.

- Decoupling Capacitor Best Practices

- Each IC: one 0.1 µF ceramic capacitor between VCC and GND.

- Every 10 ICs: add one 10 µF bulk capacitor for charge storage.

- Use capacitors with low ESR/ESL and keep leads as short as possible.

- Functional Zoning and Clock Layout Divide the board into analog, digital, and power zones. Keep clock traces short and close to load devices; optionally shield with a ground ring to reduce radiation.

5. Summary

PCB layout and routing are among the most critical aspects of electronic design.

A professional layout not only enhances performance and reliability but also minimizes EMI and simplifies manufacturing.

From component placement to grounding, from heat management to signal routing, every detail in PCB design contributes to the stability and longevity of the final product.