Project Overview

In collaboration with a leading Chinese university, TronixV developed a high-precision wafer testing platform for a confidential national research program. From initial concept to final delivery, TronixV provided a complete solution covering mechanical design, motion control, software integration, and system calibration, contributing to one of the university’s most successful scientific equipment projects.

Collaboration Background

The university’s research team faced major challenges in motion accuracy and mechanical design, as conventional dual-axis systems could not meet the required micron-level precision.

Recognizing TronixV’s proven expertise in precision mechatronics and control systems, both sides quickly established a partnership. TronixV assumed full responsibility for the end-to-end system development, including mechanical, electrical, and software engineering.

Technical Solution

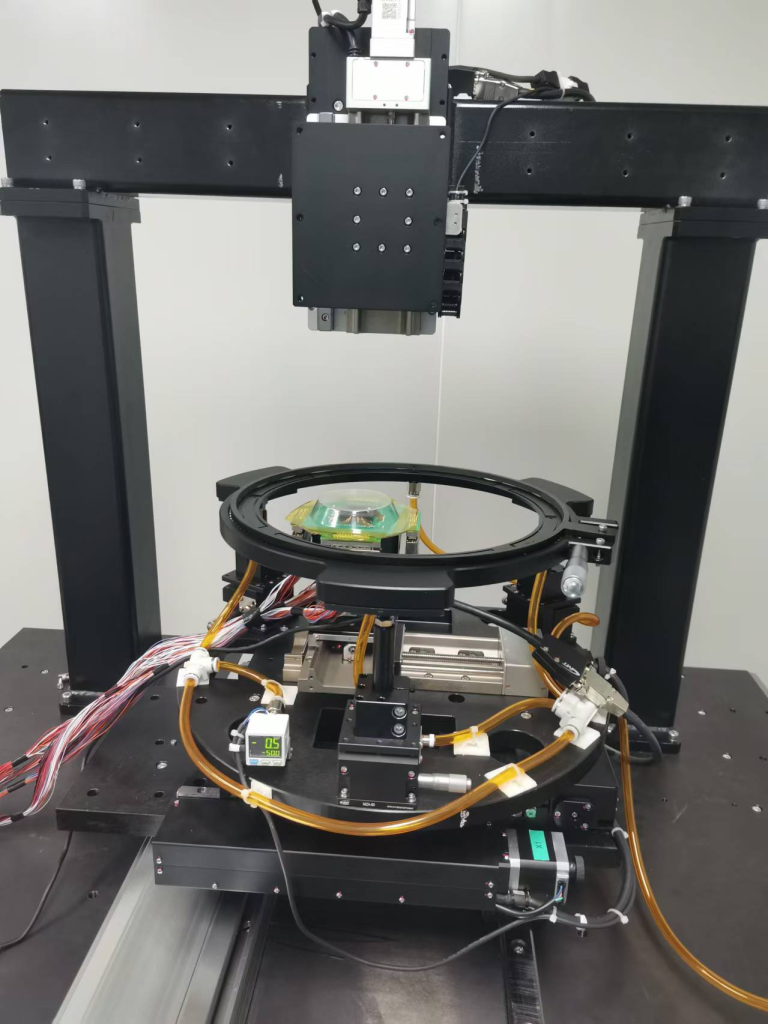

🔹 Seven-Axis Motion Platform

A breakthrough seven-axis coordinated motion platform replaced the traditional two-axis design, enabling complex multi-dimensional trajectories and postural control essential for advanced wafer analysis.

🔹 Custom Control Software

A tailor-made upper computer interface allows researchers to define motion parameters, monitor operations in real-time, and seamlessly integrate with laboratory data systems.

🔹 Micron-Level Precision Control

By employing precision linear guides, ball screws, and servo motors combined with advanced control algorithms, the platform achieves micron-level accuracy, ensuring reliable experimental results.

🔹 Integrated Technical Support

Beyond contractual tasks, TronixV engineers provided on-site assistance in system integration and data synchronization, ensuring smooth collaboration across research systems.

Technical Highlights

- Seven-Axis Synchronized Control Algorithm for multi-dimensional motion;

- Precision Mechanical Optimization minimizing vibration and coupling error;

- Micron-Level Accuracy with Long-Term Stability verified through extended testing;

- Intelligent Software Integration for real-time data acquisition and analytics.

Outcomes & Impact

The wafer testing platform was delivered on time and passed national-level project acceptance, ranking among the university’s most successful major research equipment projects that year.

Its deployment has significantly improved experimental precision, accelerated scientific progress, and demonstrated TronixV’s leadership in advanced motion control and precision engineering.

The success of this collaboration not only strengthened TronixV’s position in the high-end equipment sector but also showcased the company’s commitment to empowering China’s scientific innovation through engineering excellence.