Project Background

In the development of a 160KM centralized-power EMU, stable ventilation and cooling are essential for ensuring both safety and efficiency. As a key sensing component, the flow and wind-speed sensor must maintain high precision and reliability under harsh conditions such as vibration, temperature fluctuation, and humidity changes.

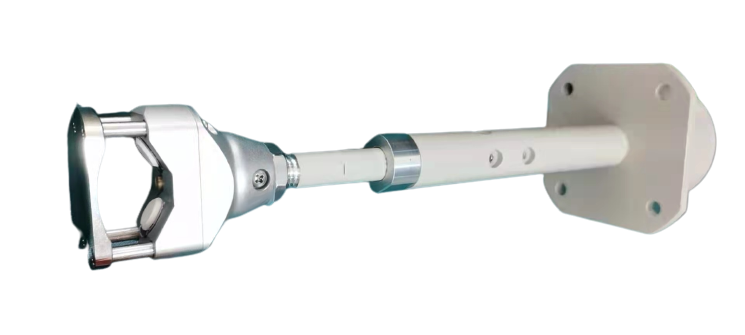

A subsidiary of CRRC commissioned TronixV to develop a customized ultrasonic flow sensor, aiming to achieve precise airflow monitoring in extreme environments.

Solution

TronixV adopted an integrated “custom hardware + self-developed algorithm” approach:

- Structural Design – Optimized vibration resistance and sealing to meet stringent railway safety standards.

- Embedded Software & Hardware – Developed a proprietary airflow sensing algorithm tailored to EMU operation, using dynamic compensation to eliminate environmental interference and ensure accurate real-time flow data.

Technical Highlights

- High-Precision Algorithm: Built on fluid dynamics simulation and real-world testing, achieving measurement accuracy within ±2%, capable of detecting even subtle airflow variations.

- High-Reliability Design: Certified under multiple railway-grade tests—temperature cycling, vibration, and EMC—using industrial-grade components to ensure MTBF > 100,000 hours and operation between –40°C and +85°C.

Results & Impact

The successfully delivered ultrasonic sensor has been mass-deployed in the new EMU series, achieving:

- 8% reduction in ventilation energy consumption;

- Lower risk of cooling system failures;

- Breakthrough in domestic substitution of key railway components. The solution also demonstrates strong potential for expansion into industrial gas flow monitoring and smart energy control applications.