Cooperation

Despite offering 2-3 times higher quotes than competitors, TronixV emerged as the sole mass-production supplier for Atlas (a Fortune 500 company) among three competing vendors.

Key Success Factors:

Proven Expertise: 10+ years of industrial design experience

Technical Superiority: Full industrial-grade isolation design

End-to-End Capability: Complete process delivery from R&D to production

Achievements:

✔ 40% cost reduction compared to traditional solutions

✔ Official certification by Atlas’ Sweden headquarters

✔ Validated execution capability through successful mass production

Project Background

Client Requirements:

Atlas (Fortune 500 company) sought to optimize costs for its automated nail feeding equipment by:

Replacing high-cost PLC solutions

Implementing microcontroller-based alternatives

Key Challenges:

First-time outsourcing partnership with high expectations

Parallel development among 3 competing suppliers

Requirement to support:

Compatibility across 6+ product lines

Rigorous reliability testing (vibration, isolation, multi-IO)

Industry Challenges:

PLC solutions:

• High cost structure

• Limited customization flexibility

Stringent supplier qualifications:

• Demonstrated technical capabilities

• Proven mass production capacity

Solution

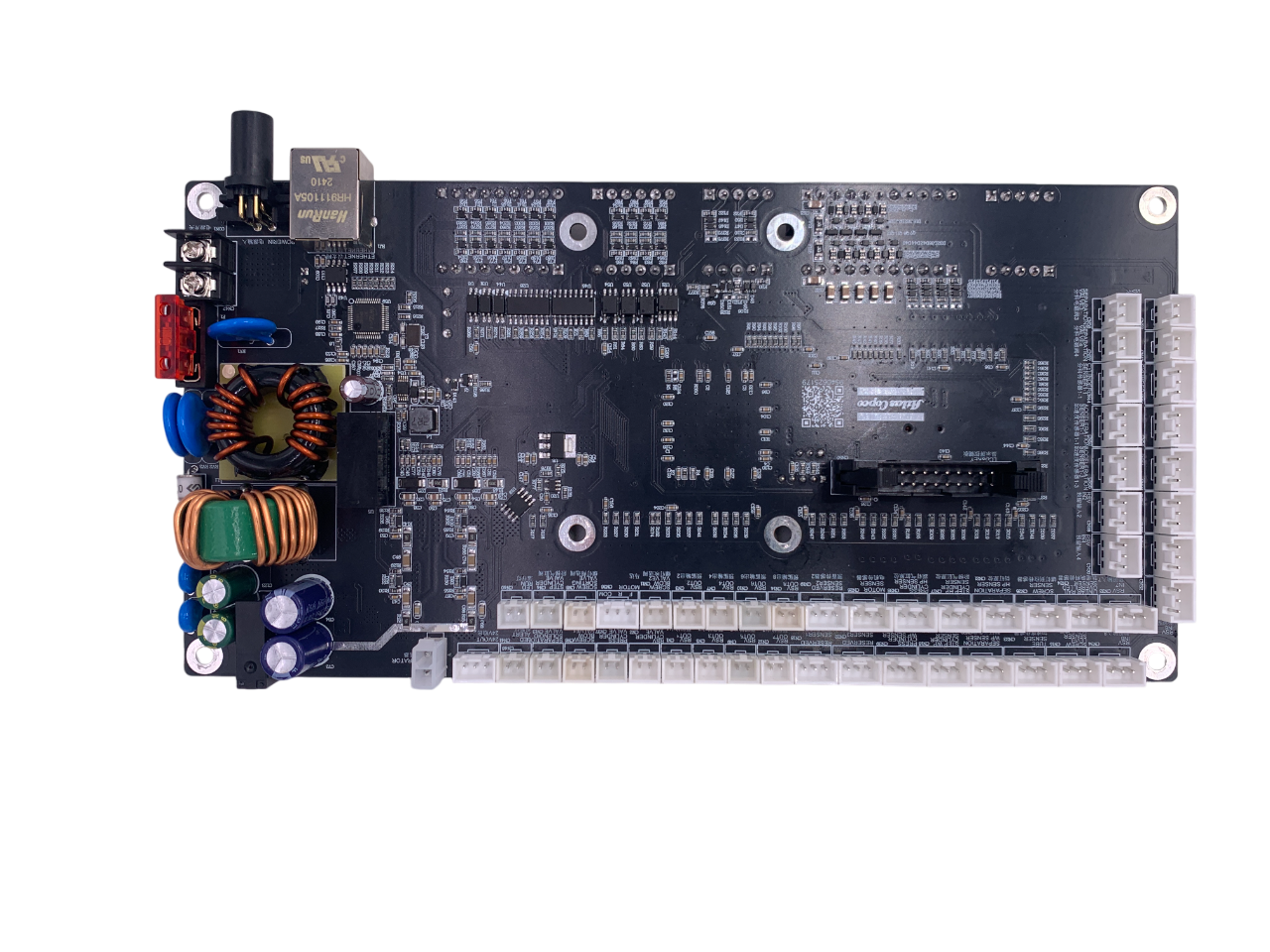

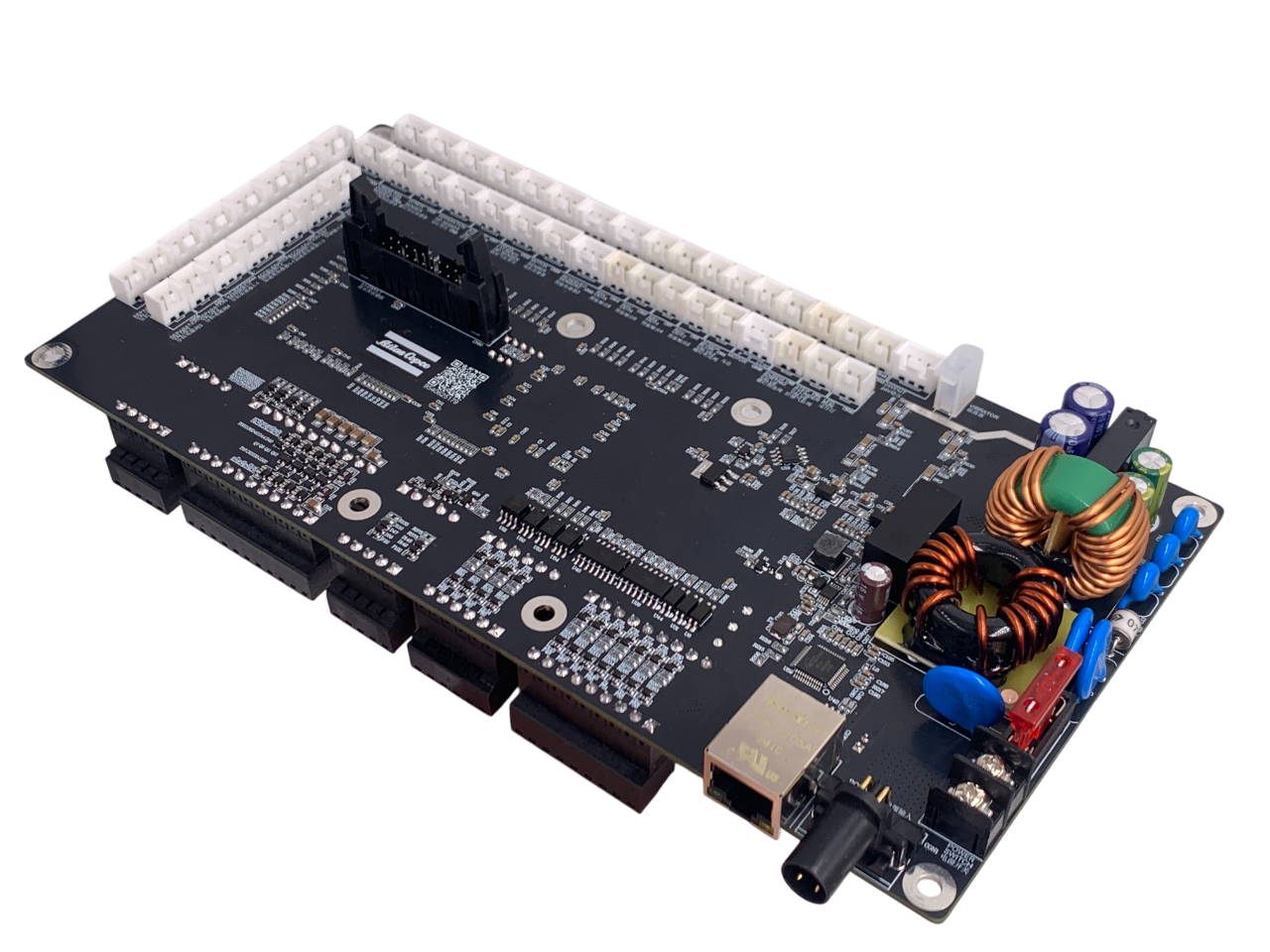

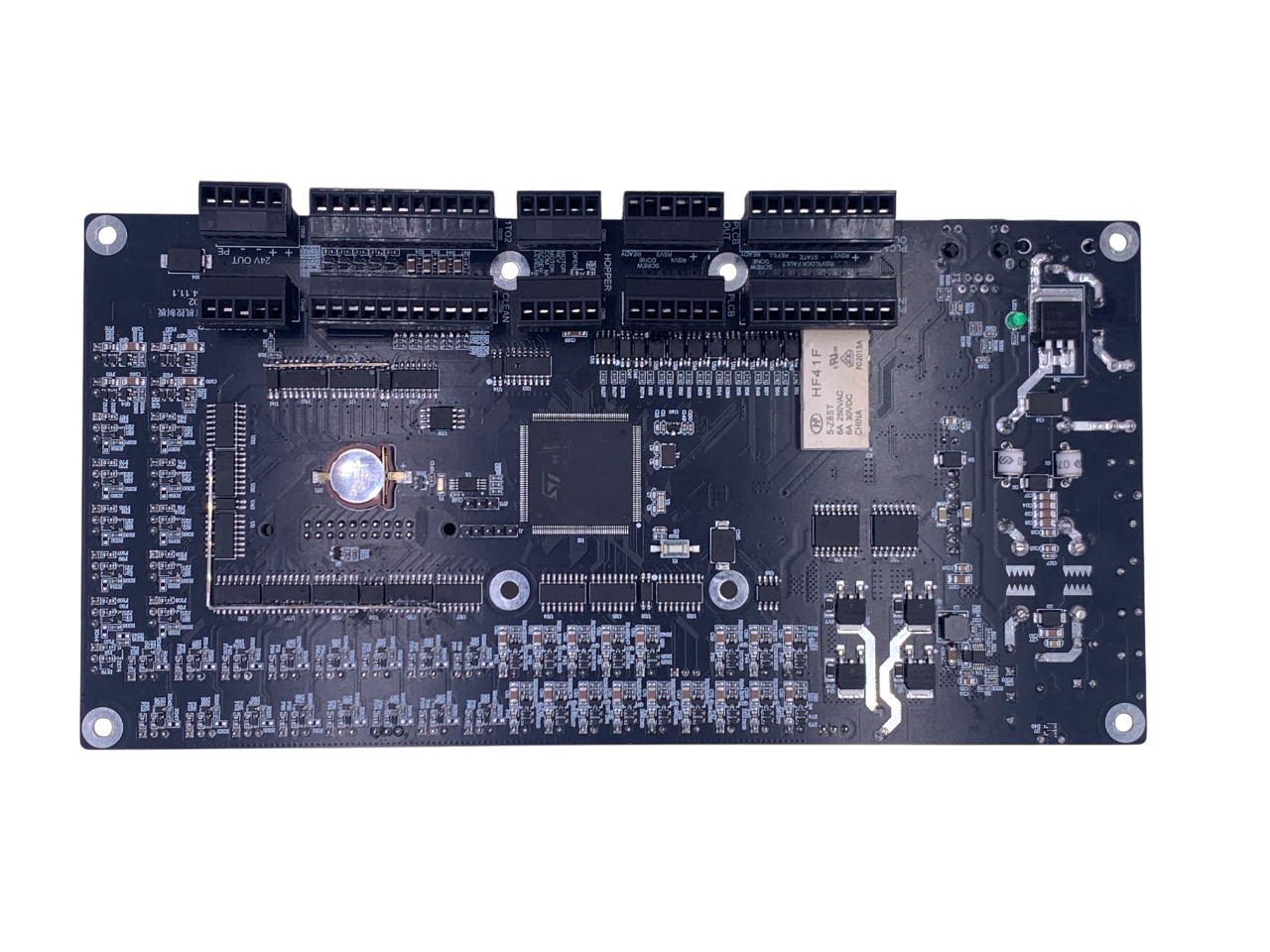

Single-Board Microcontroller Solution

A highly integrated design that replaces traditional PLCs, combining I/O control, web-based configuration, and vibration drive in a single unit. Features full isolation design for enhanced noise immunity and safety.

Platform-Based Design

A modular architecture ensures broad compatibility—a single mainboard supports 6+ product lines, fully compliant with Atlas global equipment standards, reducing both R&D and maintenance costs.

Reliability Assurance

Rigorously tested for temperature, humidity, vibration, and EMI

Backed by 10+ years of industrial design expertise

Smart voltage regulation cuts energy consumption by 15%, delivering a high-reliability, energy-efficient solution.

Technical Highlights:

Industrial-Grade MCU Solution

Features highly integrated single-board design that perfectly replaces traditional PLC systems. Integrates three core functional modules – control, communication, and drive – significantly reducing equipment costs.

Fully Isolated Design

Innovative full-isolation architecture achieves triple isolation of power supply, signals, and communication, ensuring anti-interference capability and operational safety in complex industrial environments.

Platform-Based Mainboard

Proprietary platform-based mainboard solution compatible with 6+ product lines. Greatly simplifies supply chain management and reduces inventory pressure by over 50%.

Industrial-Grade MCU Solution

Features highly integrated single-board design that perfectly replaces traditional PLC systems. Integrates three core functional modules – control, communication, and drive – significantly reducing equipment costs.

Fully Isolated Design

Innovative full-isolation architecture achieves triple isolation of power supply, signals, and communication, ensuring anti-interference capability and operational safety in complex industrial environments.

Results and Benefits:

40% Cost Reduction

Our innovative solution directly replaces traditional PLC systems, helping customers achieve up to 40% reduction in equipment costs.

Sole Mass-Production Provider

Among three competing suppliers developing parallel solutions, Tongwei emerged as the only one to successfully deliver mass-production units.

Internationally Certified

The solution passed rigorous evaluation by Atlas Copco’s Sweden headquarters, earning official certification.

15% Energy Efficiency Improvement

Equipped with intelligent voltage regulation technology, the system reduces energy consumption by 15% compared to conventional solutions.

Proven Reliability

Successfully passed customers’ stringent vibration tests, electrical isolation tests, and multi-IO interface validation, ensuring industrial-grade operational stability.