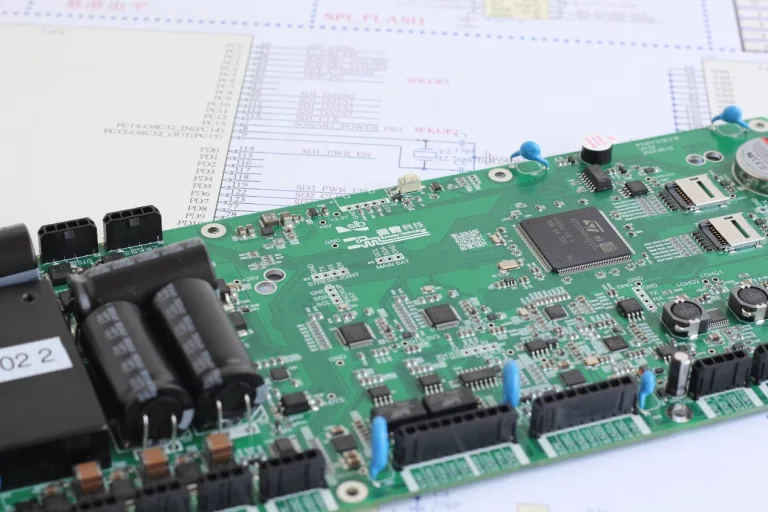

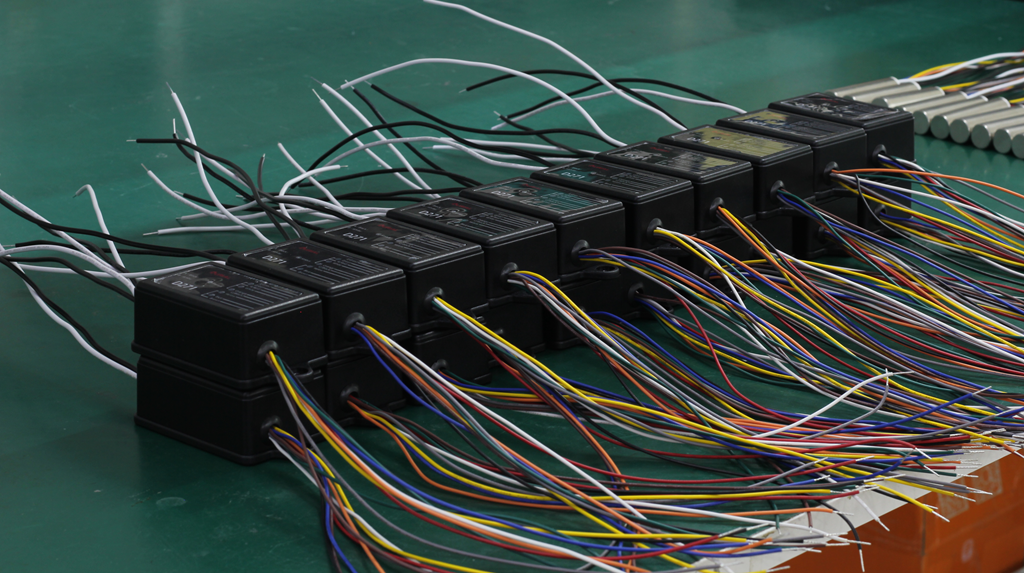

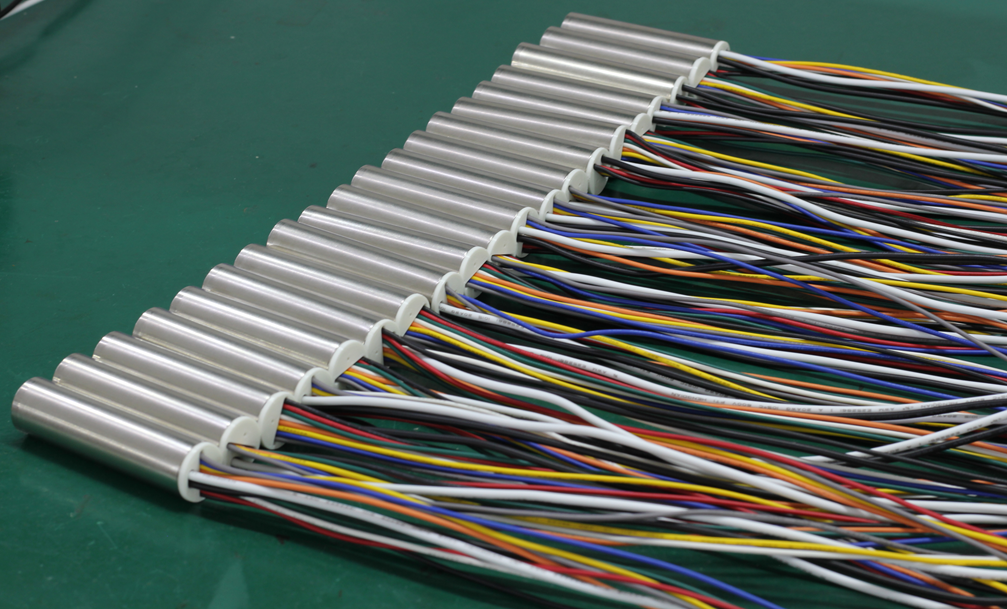

TronixV, a Chinese engineering company, has sent its high-accuracy, custom-designed cable expander (designed for a Canada customer) into small-pilot (small-batch) production following about one year of architectural design, engineering validation, and reliability testing. It features the ability to provide power and control up to 6 relay signals at the same time through only two wires, and demonstrates the integrated offering of Tronix V in custom design, reliability engineering, and scalable manufacturing enablement. TronixV PRODUCTIZATION THIS WORK Thanks to the tenacity and entrepreneurial spirit of the TronixV team, and recognizing the unforgiving nature of the HVAC space in terms of the cost and longterm stability required, TronixV introduced a brilliant productization measure: the repurposing of a mature 18650 battery metal casing as the transmitter-end enclosure.

This approach:

Eliminates new mold investment

Shortens lead time

Significantly reduces enclosure cost

Enhances solution reproducibility and manufacturability The successful launch of pilot production represents the transition from R&D validation into scalable deployment readiness, and sets a strong basis for ramp-up and for future product line extensions. TronixV is committed to driving innovative ideas for its customers faster with their integrated “Customize – Validate – Manufacture” service model.

— TronixV (Custom Design · Development · Manufacturing Services)