Cooperation

TronixV has established a long-term strategic partnership with one of the UK’s leading suppliers of power equipment and solutions.

As a key equipment provider for some of Europe’s power grids, the customer relies on TronixV to provide a full range of services from R&D to manufacturing.

Ten years of experience:

The partnership has lasted for more than ten years. TronixV has successfully delivered and iterated more than 5 RTU products of the same series of power intelligent terminals. Both parties have established a deep mutual trust and tacit understanding.

Project Background

The client needed to deploy smart terminal units (RTUs) for critical power sites for its core customer, part of the European power grid.

Key Challenges:Core Challenge:

The European power industry has very high requirements for environmental reliability, electromagnetic compatibility, electrical safety, and industry access certificates (such as CE and other specific certificates).

Customer’s pain point:

The customer lacks a hardware R&D team and urgently needs a reliable partner with profound industrial electronics R&D strength, a strict quality control system and globalized supply chain management capability to take responsibility for the whole product life cycle.

Solution

Integrated R&D and design:

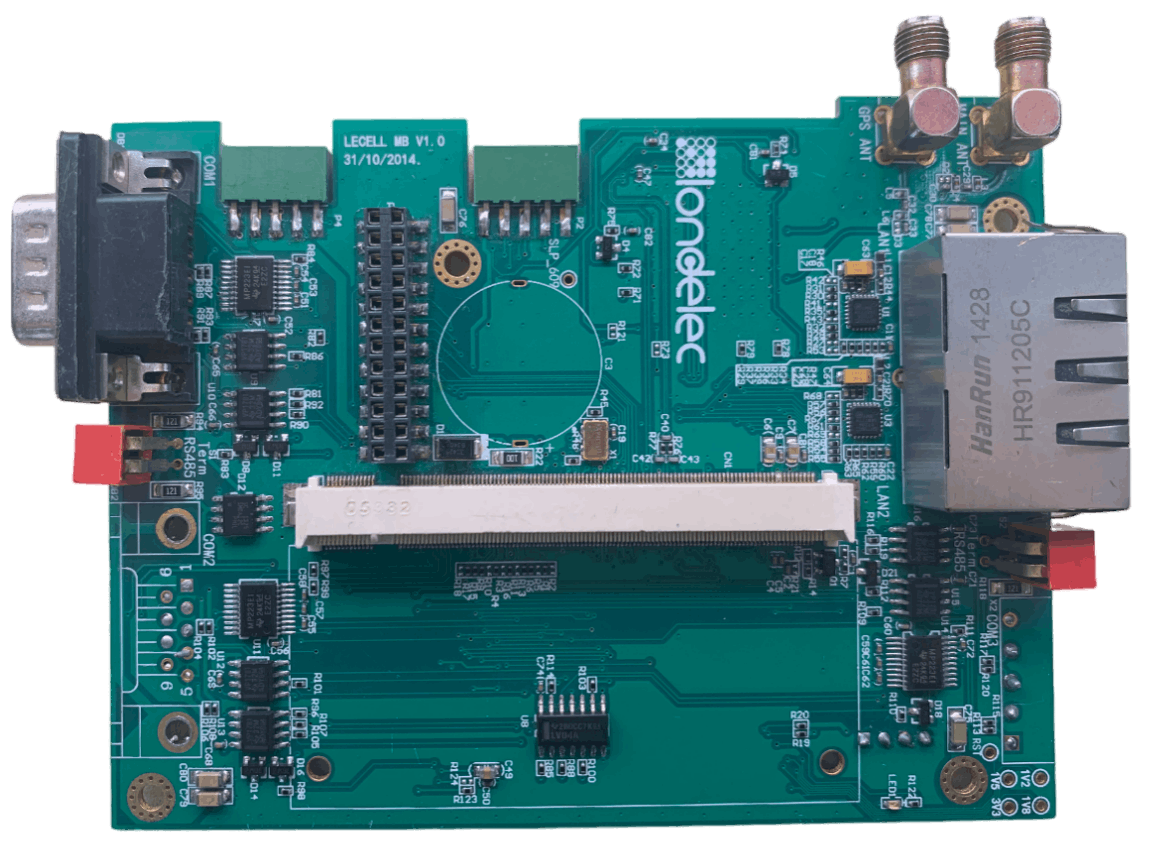

TronixV takes the lead in the design of the product shell structure and core hardware circuit design and deeply collaborates with the customer in the embedded software design and integration to ensure that the product functions and performances are perfectly suited to the needs of the electric power field.

Stringent Reliability Guarantee:In the product development stage, TronixV conducts comprehensive environmental adaptability (high and low temperature, humidity and heat, vibration, etc.), electromagnetic compatibility (EMC) and electrical safety testing and optimization. We also support our customers in completing the final testing and certification in Europe and successfully obtaining CE and other necessary industry certificates.

High-standard lean manufacturing:

We have established high-specification production lines that meet industrial-grade requirements and implemented strict global supply chain management and warehouse management to ensure the consistency and high quality of each piece of equipment. Successful mass production and stable delivery of more than 500 units to meet customer demand for continuous deployment.

Continuous Innovation and Derivation:

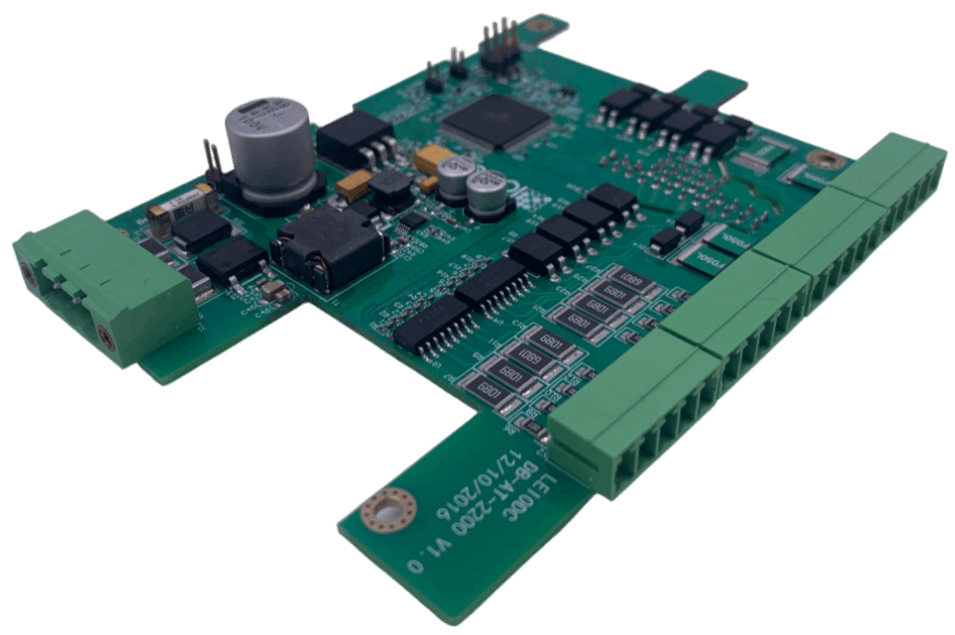

Based on the first successful product platform, TronixV has flexibly responded to customers’ needs and developed more than 5 RTUs of the same type with different functions and adapted to different scenarios, thus expanding the application boundaries of the products.

Core Technology:

Highly reliable hardware platform design:

Optimized circuit design and component selection for the electric power industry environment (strong electromagnetic interference, wide temperature, high humidity, etc.) to ensure the long-term stable operation of the hardware.

In-depth environmental adaptability and robustness:

Through professional simulation and bottoming tests, we have mastered and solved the key technology of reliability in extreme environments so that the products have excellent environmental adaptability and anti-interference ability.

Strict safety and EMC design: In-depth understanding and application of international and European electric power industry safety and EMC standards to ensure product safety and electromagnetic compatibility from the source of design, to ensure that the one-time through the stringent certification.

Scalable and modular platform:

The core hardware and software platform is highly scalable and modular, which lays a solid foundation for the rapid development of subsequent multi-model derivatives.

Globalized Supply Chain and Manufacturing Quality Control:We have established a globalized supply chain system to meet the requirements of high-end industrial electronic products and implemented strict quality control standards throughout the entire process of materials, production and testing.