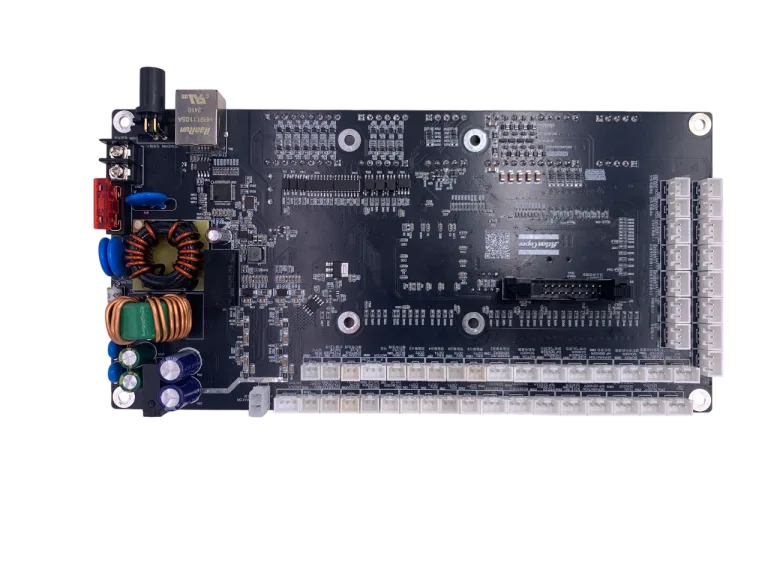

For hardware engineers, PCB design directly determines the performance and long-term reliability of electronic devices. Among all design considerations, PCB thermal design is often overlooked but plays a critical role in preventing performance degradation, instability, or permanent damage.

This article provides a complete, engineering-oriented overview of PCB thermal design — including layout optimization, component-level heat dissipation, board-level cooling strategies, and thermal resistance analysis — helping you build robust and reliable hardware systems.

Layout Design: The Foundation of PCB Thermal Design

Thermal management begins with proper component placement. A well-designed layout can significantly reduce junction temperature and improve system reliability.

1. Place high-power components in areas with good airflow

- Near PCB edges, air inlets, or regions with higher airflow

- Use CFD simulation to analyze airflow patterns in different layouts

2. Maintain sufficient spacing between heat-generating components

- Prevent heat accumulation

- Spread heat evenly across the PCB surface

3. Keep temperature-sensitive components away from hot zones

Typical sensitive components: oscillators, memory, MCUs, CPUs

Guidelines:

- Natural convection (sealed case): place sensitive components at the bottom

- Natural convection (unsealed): near air inlet

- Forced air cooling: in the airflow inlet zone

4. Use airflow distribution to optimize placement

- High-velocity airflow areas are ideal for high-power components

- Avoid large empty regions along airflow paths

5. Stagger heat-generating components along airflow direction

- Reduce thermal stacking

- Avoid downstream components overheating due to airflow shadowing

6. Consider the influence of heat sinks

Heat sink bypass airflow may:

- Increase heat transfer of side components

- Strengthen or weaken cooling of downstream components → requires monitoring

Thermal Design for Different Component Packages

Each package type has a different heat path, so thermal design must be package-specific.

1. THD components

- Limited thermal conduction to PCB

- Mainly rely on surface convection → Focus on airflow enhancement

2. SMD components

- Strong thermal coupling with PCB

- PCB becomes a major heat path → Central consideration in PCB thermal design

Enhancement strategies include:

- Thermal pads

- Large copper areas

- Thermal via arrays

3. PGA / BGA

- Used in CPUs, GPUs, ASICs

- Rely on heat sinks + thermal interface materials + forced air cooling

Practical Case

A thermal model mismatch in TIM thickness (0.3 mm vs. Intel’s 0.13 mm) caused a 20°C difference in CPU junction temperature.

→ TIM thickness is a critical parameter in PCB thermal design.

PCB-Level Heat Dissipation Techniques

1. Large copper pours

- Larger copper area = lower junction temperature

- Suitable for MOSFETs, DCDC modules, power ICs

2. Thermal vias

Benefits:

- Improve vertical heat transfer

- Provide heat path to the back of the PCB

Simulation shows:

- 6×6 thermal vias reduce junction temperature by 4.8°C

- Reducing to 4×4 increases temperature by ~2.2°C

3. Exposed copper on IC bottom pads

- Reduces air-interface thermal resistance

- Works best with surface treatment and coatings

4. Follow IPC-2221B guidelines

Ensure thermal design does not compromise electrical or mechanical performance.

Thermal Resistance Analysis

Thermal conduction can be compared to electrical conduction:

- Temperature difference ↔ Voltage

- Heat transfer ↔ Current

- Thermal resistance ↔ Electrical resistance

Key parameters

- Rjc: Junction-to-case resistance

- Rja: Junction-to-ambient resistance

- Conduction resistance: δ/(λA)

- Convection resistance: 1/(αA)

Contact thermal resistance

- Caused by micro-air gaps between two surfaces

- Reduced by higher pressure or thermal interface materials (TIMs)

Improvements

- Selecting proper TIM materials

- Optimizing TIM thickness

- Increasing airflow

- Using larger or more efficient heat sinks

- Reducing power consumption of the source device

Conclusion

PCB thermal design is a multi-disciplinary engineering process requiring careful balancing of layout, copper distribution, thermal vias, package thermal characteristics, and industry standards.

With extensive real-world experience in PCB thermal design, RF pcb design, EMC, and high-speed layout, Tronixv provides professional hardware development services that ensure reliability even under extreme operating conditions Contact us.