Cooperation

Atlas (fortune 500 company in Sweden which is engaged in industrial equipment), with a quotation 2 to 3 times higher than others. TronixV became The sole mass production for distributors, among three selected suppliers chose by Atlas. The company engaged three providers in parallel, and rejected two based on their lack of capability. TronixV has released another product that has successfully entered mass production, and it has another success story through years of product implementation experience and high-quality service, which once again illustrates the strong product design and implementation capabilities of TronixV.

Project Background

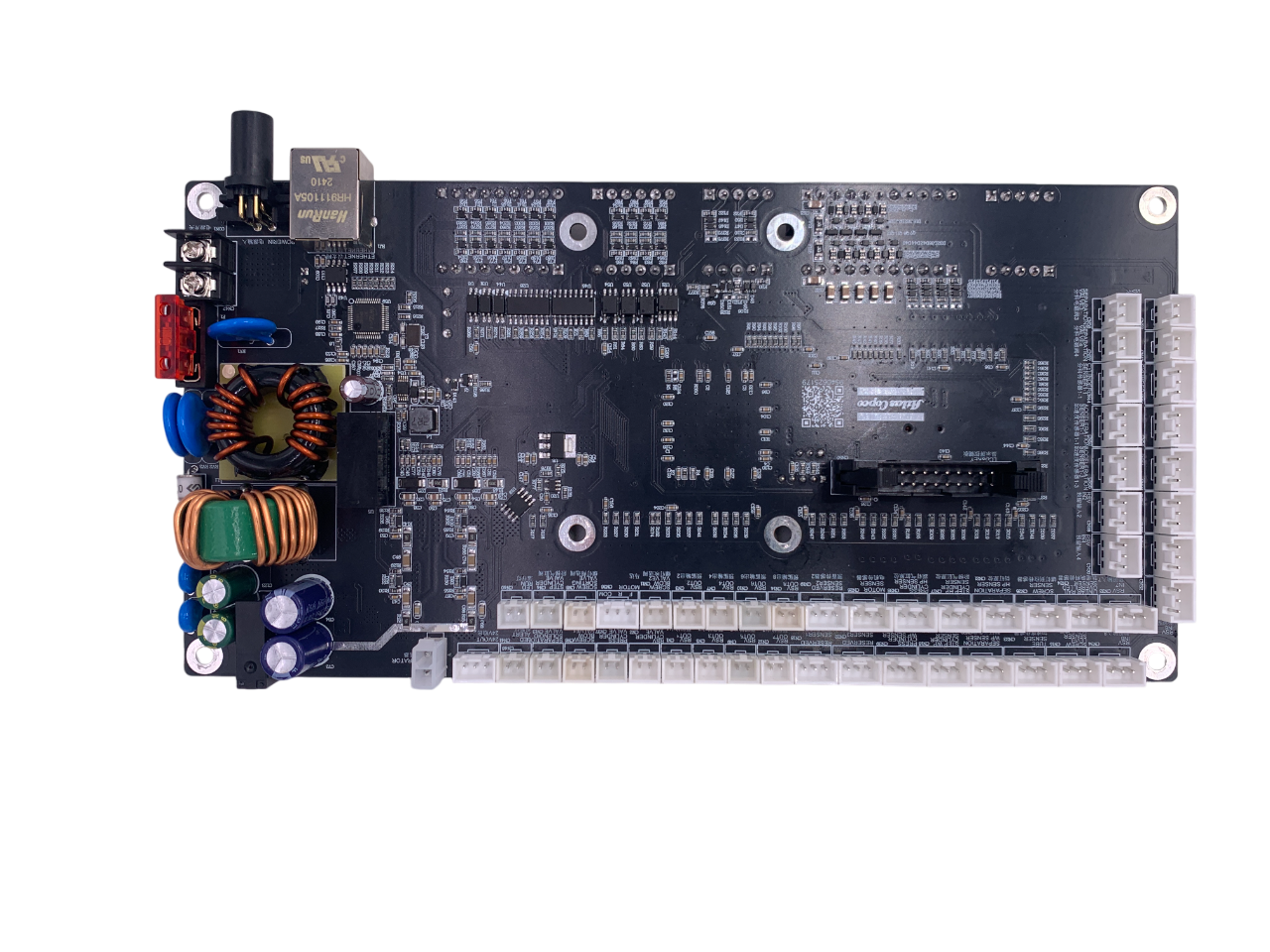

Client Requirements: Atlas wanted to reduce the cost of their automated assembly line nail feeding system, and migrate from a PLC-based solution to a single-chip microcontroller solution.

Challenges: This was Atlas’ inaugural outsourcing partnership, and to play it safe, they contracted with three developers at once. In addition to which, the client was not well-versed with the single-chip microcontroller solutions and hence were not able to freeze their requirement.

Solution

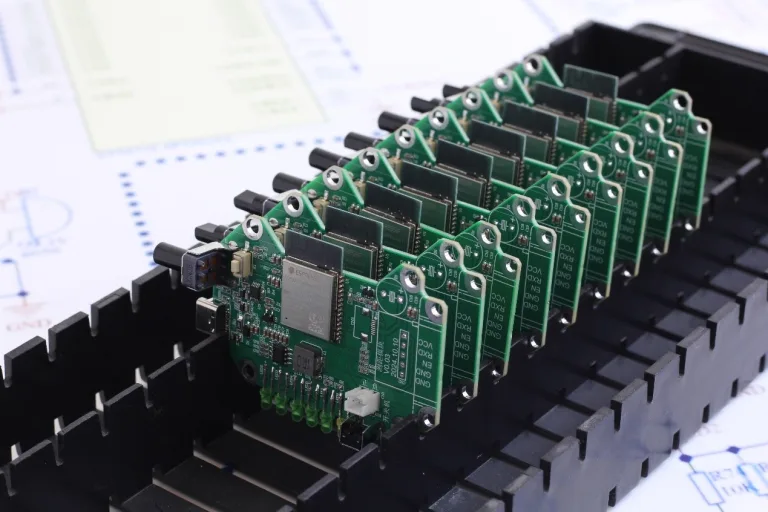

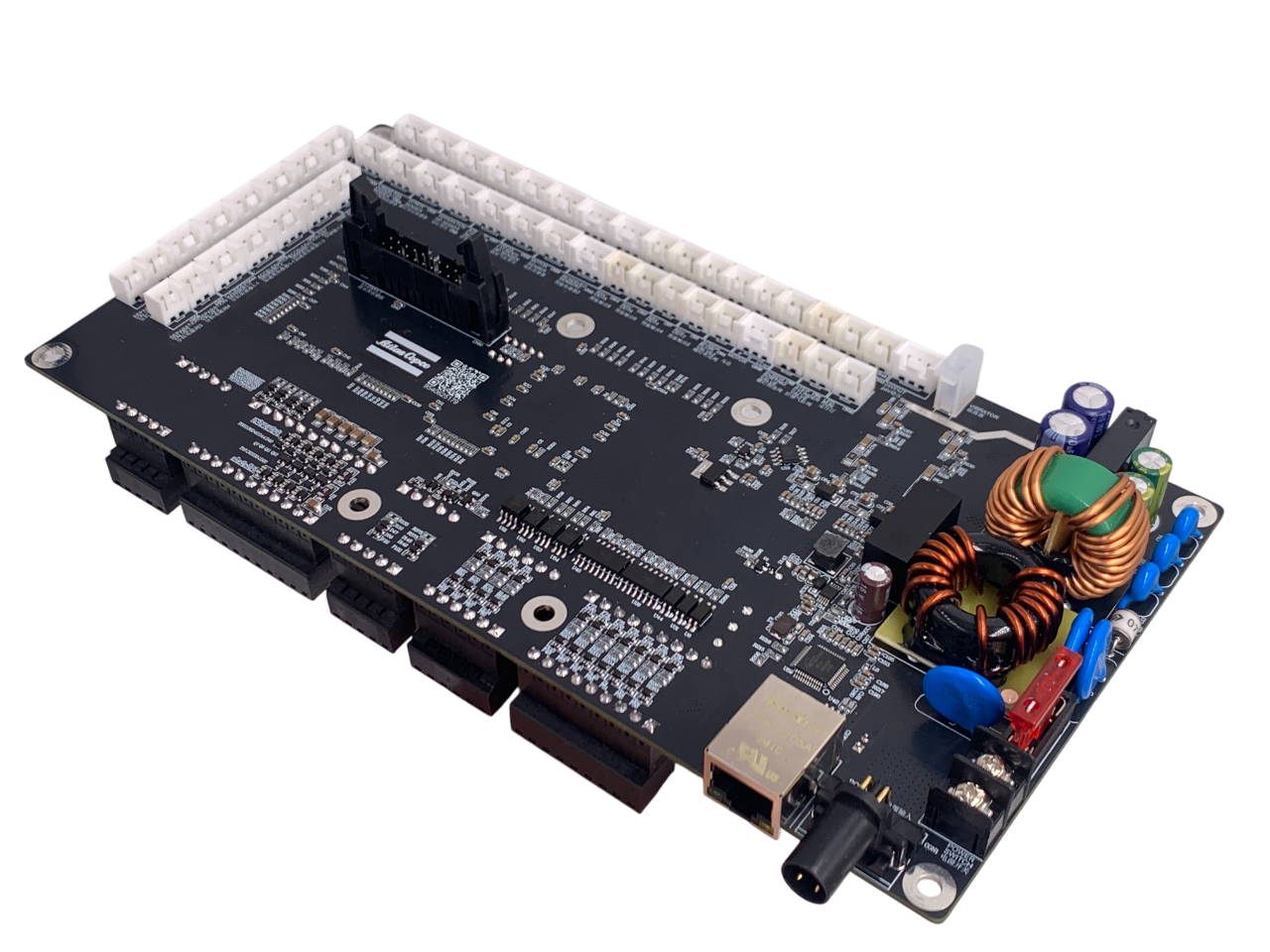

Single-board solution with microcontroller: Alternative for PLC with I/O control and Web-configuration, Vibration drive, Industrial response and Galvanic isolation.

Design Platform: One motherboard with many interfaces, supports more than 6 products. Reliability Assured: Product reliability is assured by various reliability test in field such as Temperature Test, Humidity Test, Vibration Tests and EMI Test.

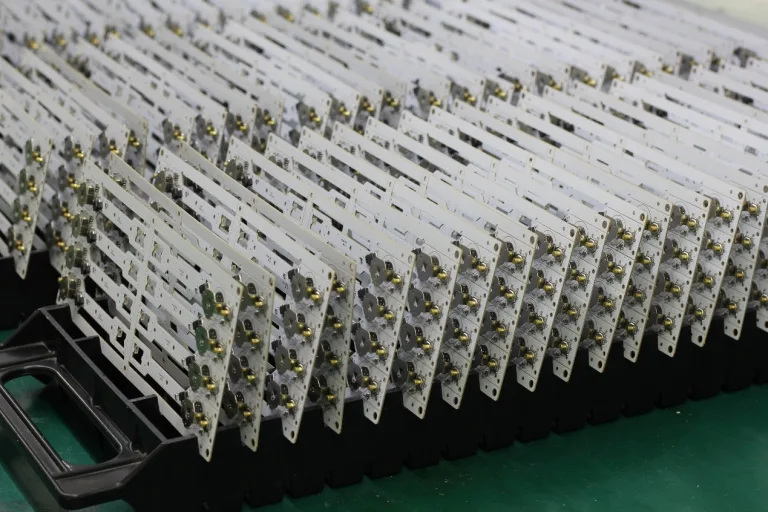

· DFM Design: Follow industry DFM design rigor, mass production after design finish.

Achievements and Benefits:

Thanks to the successful product development made by Atlas yet again, customers have also seen a substantial drop in hardware costs and become a fabulous good start for TronixV Technology.