In the field of electromagnetic compatibility (EMC) technology, we have always pursued two main goals: simple and easy quantitative index assignment, and low-cost and operable visualization test methods. In this paper, we will focus on the latter and discuss several practical, visual locations of the noise source of the test means.

1. Commonly used visual noise test methods

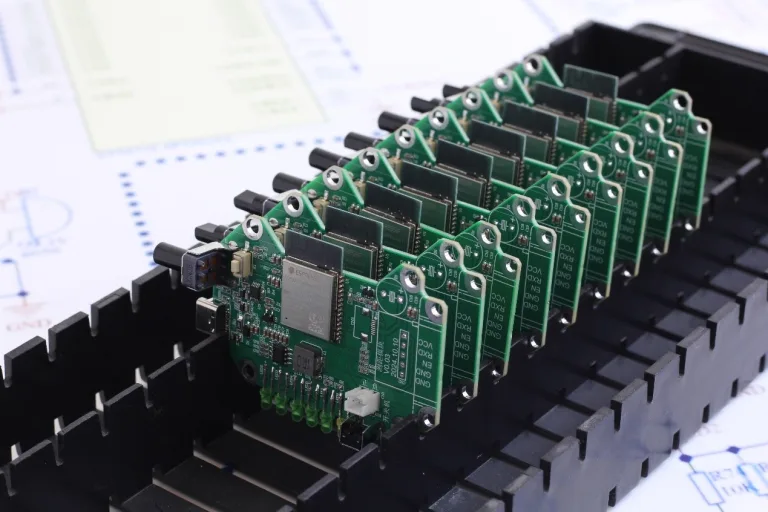

Near-field Probe + Low Noise Amplifier + Spectrometer (Spatial Radiation Scanning)

Principle and Application: This method captures the electromagnetic field near the circuit board or equipment through a near-field probe, which is amplified by a low-noise amplifier, and then displayed by a spectrometer to show the noise spectrum in a specific region of space. It is particularly useful for detecting radiated noise from higher-frequency signals, as low-frequency signals are often difficult to radiate effectively.

Advantage: Effective in finding envelope noise (broadband noise).

Limitations: The noise spectrum is measured over an area, making it difficult to pinpoint a specific individual wire or source directly. A more detailed investigation and analysis are required in hot spots.

Oscilloscope + FFT (time domain waveform to frequency domain analysis)

Principle and Application: An oscilloscope is used to measure the voltage waveform directly at the test point on the circuit board, and its FFT (Fast Fourier Transform) function is enabled to convert the time domain waveform into a spectrum. This clearly identifies the frequency components of the noise.

Key Points: The choice of window function is crucial, directly affecting the clarity of the spectrum and the effect of side-valve suppression (involves the details of Fourier Transform theory, will not be expanded here).

Recommended window functions: Hanning and Blackman. These two window functions can effectively reduce the spurious spectrum on both sides of the target noise frequency, making the main frequency more prominent and easier to read.

Current Clamp + Oscilloscope + FFT (Cable Current Noise Analysis)

Principle and Application: The principle of this method is similar to that of Type 2, with the core difference being the use of current clamps to measure the current signal on the wire non-invasively. The current clamp converts the current signal into a voltage signal, which is then captured by an oscilloscope and analyzed by an FFT.

Advantage: Particularly suitable for scenarios such as connecting cables or power cables between boards, the current clamp’s clamping operation is quick and easy without disconnecting the circuit.

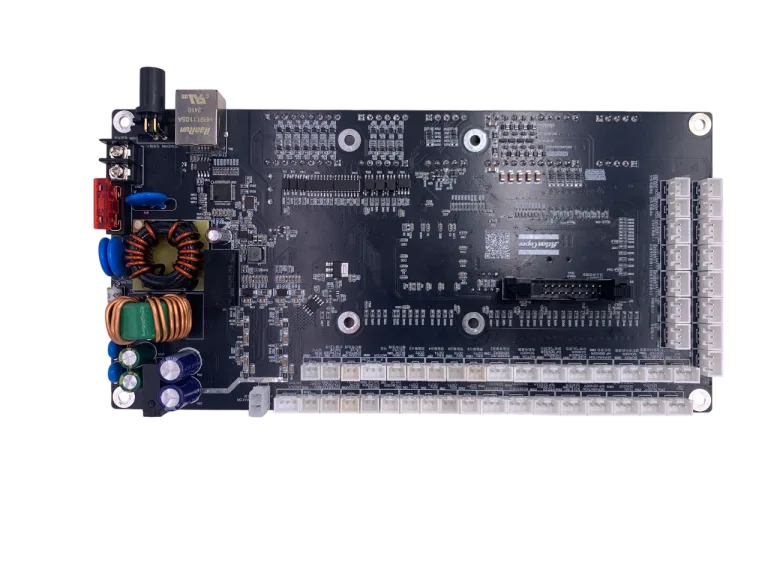

Frequency Needle + Spectrometer (Direct Detection on Board)

Principle and Application: The frequency pin is used to make contact measurement directly on the test points or component pins on the board, and the signal is directly input to the spectrometer to observe the spectrum. This is a low-cost (frequency pin price is usually about 100 dollars, common market) and direct on-board noise detection method.

Advantage: Simple and direct operation, low cost.

Question to ask: Despite the significant advantages of this method (low cost, simplicity, directness), it does not seem to be widely used in the industry. The reasons behind this (e.g., contact reliability, ability to detect small signals, or the engineer’s habits) deserve further thought and discussion.

2. The core concept of noise traceability: the “DNA” property of frequency

Regardless of which of the above methods is used to obtain the noise spectrum, the core principle of locating the source of noise is to understand the “immutable properties” of the noise frequency. This is similar to the DNA inheritance property in biology – the similarity of DNA between father and son is not affected by the acquired environment (e.g., diet, education, occupation). In the field of electronic noise

A significant noise frequency, f_noise, measured somewhere in a circuit, almost inevitably originates from one of the circuit’s fundamental operating frequencies, f_clock, or one of its harmonics (n is a positive integer).

That is, the relationship f_noise = n * f_clock or f_noise = m * f_clock (m, n being positive integers) must hold.

Using this principle, we can act like a detective solving a crime:

Identify the “victim” (disturbed circuit or signal) — measured noise frequency f_noise.

Find the “criminal” (source of noise). Find the “criminal” (the source of the noise)—reverse the relationship f_noise = n * f_clock to derive the potential source clock frequency f_clock.

Analyze the “criminal process” (coupling path)— Once the source is identified, it is relatively clear to analyze how the noise propagates from the source to the point of victimization (conduction or radiation).

With the source (offender), the victim, and their relationships clearly identified, the development of effective “crime prevention” strategies (EMC suppression measures) will naturally have a clear direction.

3. An important special case: the absence of crystal harmonics

A common exception that requires special attention is the crystal oscillator signal. Since its output is usually a square wave with a duty cycle of 50% (1/2), its even harmonics (2k times, k being a positive integer) have a theoretical amplitude of zero or very low. Therefore:

If a significant f_noise = 2k * f_crystal (f_crystal is the frequency of a particular crystal) is observed on the spectrum, then it is highly likely that the noise is not directly radiating/conducting from the even harmonics of that crystal.

It is more likely to come from:

Harmonics (n * f_pll) of frequency f_pll (f_pll = M * f_crystal) are generated when the crystal signal is internally multiplied (e.g., PLL phase-locked loop) by some chip. Or from the modulation products of other circuits on this crystal frequency or its harmonics.

Knowledge of this property is critical to accurately troubleshooting sources of interference.