Introduction

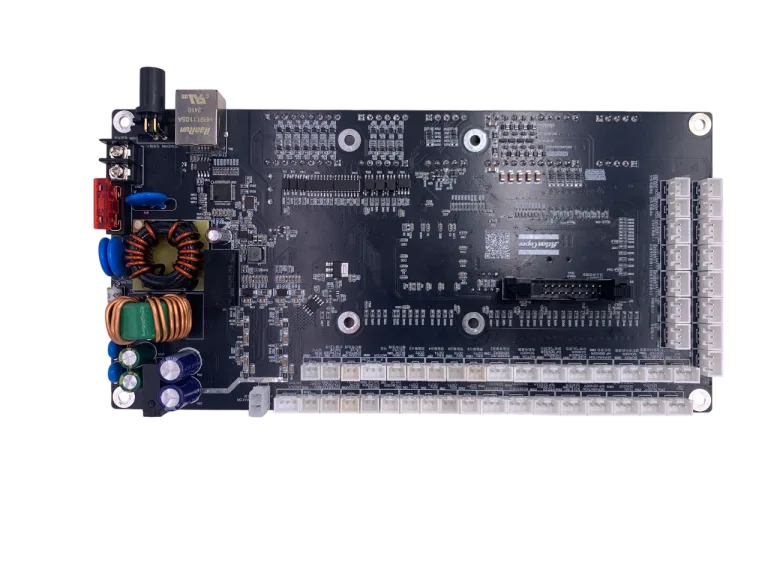

During electronic manufacturing or repair, it’s common to find residual solder or flux on circuit boards.

If not properly cleaned, these residues can lead to poor connections or even short circuits.

Thanks to modern tools and improved techniques, there are now various efficient ways to remove solder safely.

In this article, we’ll introduce two practical methods for cleaning solder from PCBs.

1. Two Scenarios of Solder Removal

There are generally two situations where solder cleaning is needed:

- Removing existing solder from a circuit board — for rework or component replacement.

- Cleaning excess solder and residue after soldering — during final production stages.

For both, it’s recommended to use a desoldering pump or desoldering braid, which ensures efficiency and precision.

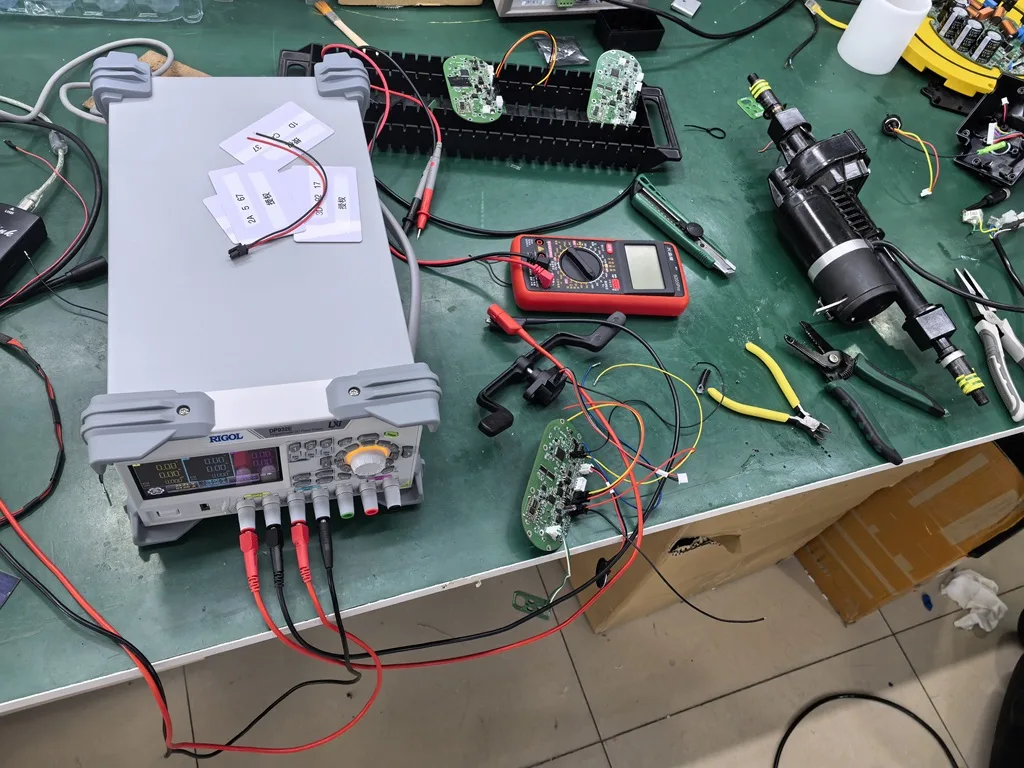

2. Method 1: Removing Existing Solder

When you need to rework or replace components, follow these steps:

- Clean the soldering iron tip Shake off excess solder from the iron, then reheat the solder joint several times until it loosens.

- Use a wire to absorb solder Take a short multi-strand wire, apply flux, and heat it together with the solder joint. Pull it away quickly while hot — it will absorb most of the solder.

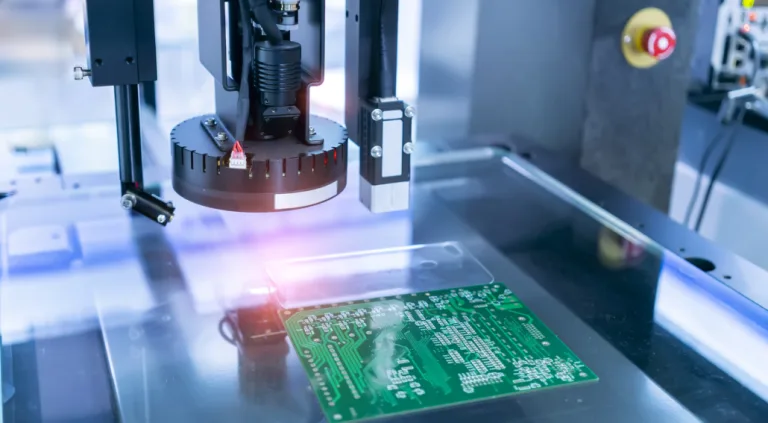

- Use a hot air gun or solder pot For large solder areas, use a hot air gun or a solder pot for uniform heating. ⚠️ Be careful not to overheat the PCB or nearby components.

3. Method 2: Cleaning Residual Solder and Flux

After soldering, residual flux or solder splashes can affect both performance and appearance.

Follow these steps to clean them properly:

- Clean with isopropyl alcohol Dip a soft brush in anhydrous ethanol (or 95% alcohol) and gently scrub the board surface.

- Dry the surface Use degreased cotton to absorb moisture and remove remaining flux.

- Use desoldering tools for vias For double-sided boards, use a desoldering pump or syringe needle to clear solder-filled holes.

- Without a desoldering tool If no tool is available, reheat the solder and gently shake the board to remove it — do this carefully to avoid burns or damage.

4. Conclusion

Proper solder removal is a vital part of PCB maintenance and assembly.

It ensures reliable connections and extends product lifespan.

Using tronixv professional soldering and PCB cleaning tools can significantly improve the efficiency, safety, and precision of the process.