A client in the livestock industry visited to discuss a PCB implementation plan for an automatic vaccine injector.

During the technical discussion, TronixV didn’t limit its role to PCB design but deeply analyzed the overall product concept,

identifying major optimization opportunities beyond the original scope — ultimately helping the client achieve a qualitative improvement in product design.

Problem

The client’s initial design relied on two manual knobs for fluid control and mode switching.

Operators had to follow on-screen prompts, frequently turning the knobs to complete each step (extracting, diluting, refilling, etc.).

Based on extensive product experience, TronixV identified multiple issues:

- High user learning curve and large training cost;

- Complex fluid pipeline prone to misuse;

- Long-term high maintenance and after-sales cost.

Solution

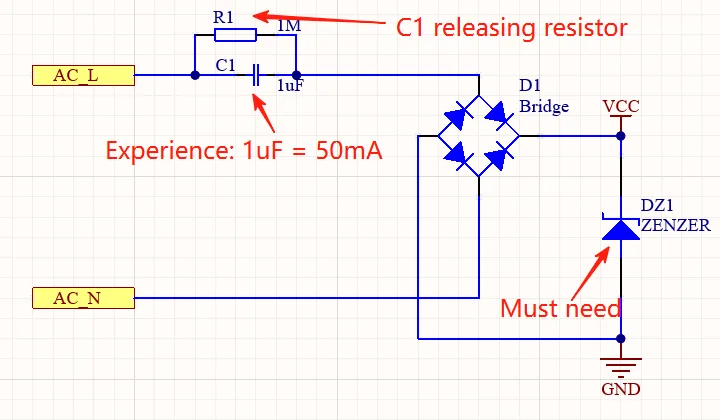

TronixV proposed a fully electronic and automated control approach:

- Replace the two manual adjustment valves with two 2-position 3-way solenoid valves;

- Use the motherboard for electronic logic control, automating the extract–dilute–return sequence.

This change simplified the liquid flow path and transformed the operation process from manual and mechanical to intelligent and automated.

Results

- Before: Button + Knob operation for extraction → Knob reset → Button + Knob for dilution → Reset → Completion;

- After: One button → Automatic process.

The simplified process dramatically reduced user training cost and improved operational reliability,

resulting in a more practical, scalable, and user-friendly product.

Client Feedback

The client praised TronixV for thinking beyond engineering tasks and proactively helping optimize the entire product system.

As the client stated:

“With TronixV, PCB manufacturing things just get done.”

A simple sentence — yet the highest form of recognition.