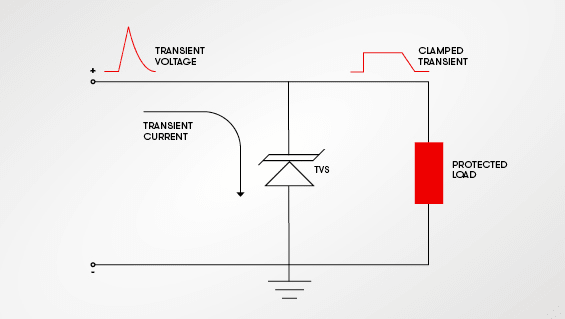

TVS devices of the same specification from different manufacturers should not be replaced arbitrarily. The most obvious difference between them is that their failure rates are likely to be different, and even significantly different. What is the reason?

The overall machine failure caused by the device itself often occurs in two aspects:

1) Design issues of devices (including material composition, structure, etc.);

2) Batch production consistency issues of devices (process, quality control process capability, etc.);

Methods for identifying device design issues:

Randomly select a few, measure their main parameter indicators, and compare their differences. If there is an overall parameter deviation in any company, then analyze the structural and material parts that cause this parameter deviation, and determine which part of the difference caused the overall parameter deviation.

Differences in Device Batch Consistency:

Extract a certain number of samples with statistical value (at least 30, accurate data needs to be calculated based on confidence interval theory), and then test certain parameters (parameters that are sensitive to materials, processes, and environmental conditions). This test may vary for different types of devices. For example, the sensitive parameters of TVS include: leakage current under fixed voltage, withstand voltage under the same leakage current, withstand voltage variation under temperature rise, and leakage current variation under temperature rise.

Determine the batch consistency of two TVS based on the normal distribution characteristics of the test values.

Material manufacturers should not easily replace them. Once they have been used for a long time, do not switch them back and forth due to cost issues. It is almost certain that there will be problems if replaced, and there will be differences in the device characteristics and batch consistency between any two companies.