Printed Circuit Boards (PCBs) form the backbone of virtually every electronic device we use today, from smartphones and computers to automotive systems and medical equipment. Understanding what PCBs are and how they function is essential for anyone interested in electronics, engineering, or technology. This comprehensive guide explores everything you need to know about PCBs, their types, purposes, and common misconceptions.

What Is a PCB?

A Printed Circuit Board (PCB) is a flat, insulating board made from materials like fiberglass, composite epoxy, or other laminate materials. The board features thin copper pathways, called traces, that are etched or printed onto its surface to create electrical connections between different components. These copper traces replace traditional wire connections, making electronic devices more compact, reliable, and cost-effective to manufacture.

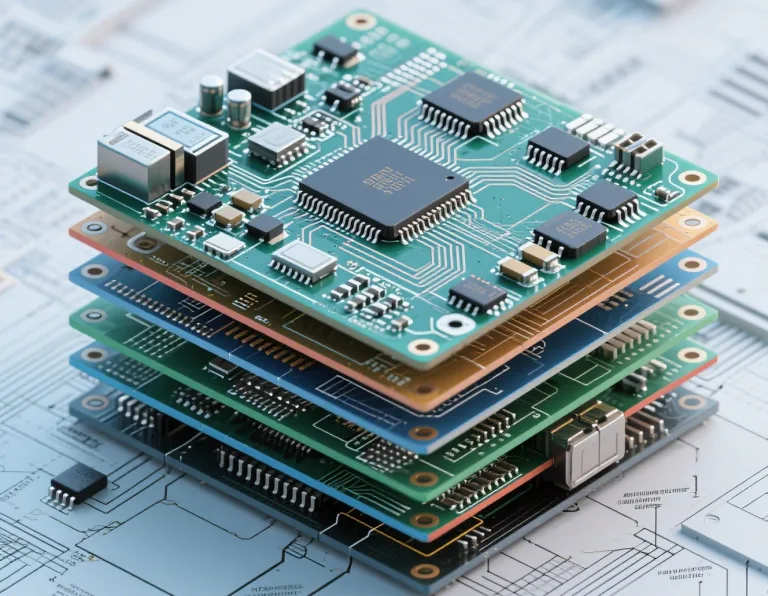

PCBs serve as the foundation for mounting and connecting electronic components such as resistors, capacitors, integrated circuits, and connectors. The board provides both mechanical support and electrical connectivity, allowing complex circuits to be assembled in a organized and space-efficient manner. Modern PCBs can be incredibly sophisticated, featuring multiple layers of circuitry stacked together to accommodate dense component layouts.

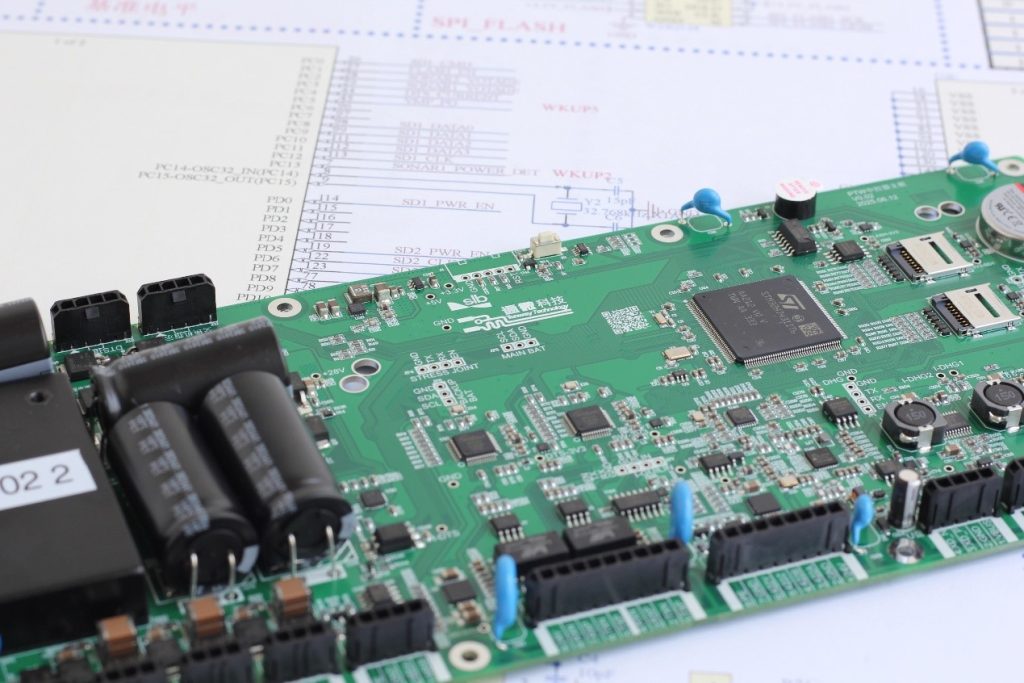

The manufacturing process involves several steps, including design layout, substrate preparation, copper application, etching, drilling, and component mounting. Advanced PCBs may undergo additional processes like surface treatment, solder mask application, and silkscreen printing for component identification.

What Are the Types of PCBs?

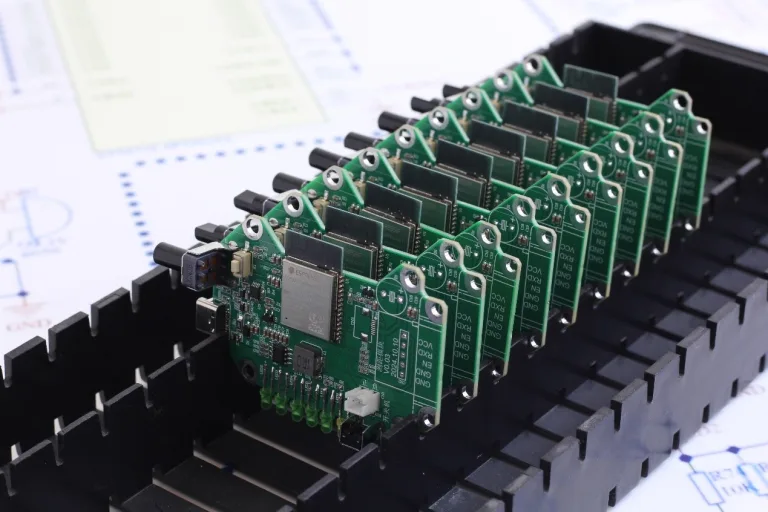

PCBs come in various configurations to meet different application requirements. Understanding these types helps in selecting the right PCB for specific projects and applications.

Single-Layer PCBs represent the simplest form of printed circuit boards. These boards have copper traces on only one side of the substrate, making them ideal for basic electronic devices like calculators, LED lighting, and simple power supplies. Single-layer PCBs are cost-effective and easy to design, but they’re limited in terms of circuit complexity and component density.

Double-Layer PCBs feature copper traces on both sides of the substrate, connected through vias (small holes with conductive material). This configuration allows for more complex routing and higher component density compared to single-layer boards. Double-layer PCBs are commonly used in more sophisticated devices like amplifiers, power converters, and intermediate-complexity electronic systems.

Multi-Layer PCBs consist of three or more copper layers separated by insulating materials. These boards can have anywhere from four to thirty or more layers, depending on the application requirements. Multi-layer PCBs are essential for complex electronic devices like computers, smartphones, medical equipment, and aerospace systems where space constraints and signal integrity are critical factors.

Rigid PCBs use solid, inflexible substrate materials like FR4 fiberglass. These boards maintain their shape under normal operating conditions and are suitable for applications where the PCB won’t need to bend or flex during use.

Flexible PCBs use flexible substrate materials that allow the board to bend and conform to different shapes. These are ideal for applications where space is limited or where the PCB needs to fit into curved or moving assemblies, such as in wearable electronics or compact devices.

Rigid-Flex PCBs combine elements of both rigid and flexible boards, featuring rigid sections connected by flexible sections. This hybrid approach provides the stability of rigid boards where needed while offering flexibility in specific areas.

What is the Purpose of a PCB Board?

PCBs serve multiple critical purposes in electronic systems, making them indispensable components in modern technology.

The primary purpose of a PCB is to provide electrical connectivity between electronic components. The etched copper traces create precise pathways for electrical signals to travel between different parts of the circuit, eliminating the need for complex wire harnesses that would be bulky, unreliable, and difficult to manufacture consistently.

Mechanical support is another crucial function of PCBs. The board provides a stable platform for mounting various electronic components, ensuring they remain in proper position during operation, handling, and environmental stress. This mechanical stability is essential for maintaining reliable electrical connections and preventing component damage.

PCBs enable compact design by allowing components to be placed close together in a organized manner. Without PCBs, electronic devices would require significantly more space to accommodate all necessary wiring and components, making modern portable electronics impossible.

Signal integrity is maintained through careful PCB design. The controlled impedance of traces, proper grounding techniques, and strategic component placement help minimize electromagnetic interference and signal degradation, ensuring reliable operation of sensitive electronic circuits.

Cost efficiency in manufacturing is achieved through PCBs by enabling automated assembly processes. Components can be placed and soldered using machines, reducing labor costs and improving consistency compared to hand-wired circuits.

Reliability and durability are enhanced through PCB design. Properly manufactured PCBs can withstand environmental stresses like temperature variations, vibration, and humidity better than traditional wired circuits, leading to longer product lifespans and reduced maintenance requirements.

Do Printed Circuit Boards Contain PCBs?

This question often arises due to confusion between two different meanings of the acronym “PCB.” It’s important to clarify this common misconception to avoid confusion in technical discussions and procurement processes.

Printed Circuit Boards (the electronic components) do not typically contain Polychlorinated Biphenyls (the chemical compounds) in modern manufacturing. Polychlorinated Biphenyls were synthetic chemical compounds once used in various industrial applications, including some electronic components, due to their chemical stability and insulating properties.

However, PCBs (the chemicals) were banned in most countries, including the United States, in the late 1970s due to their environmental persistence and potential health risks. The EPA prohibited the manufacture, processing, and distribution of PCBs in 1979, with some limited exceptions for existing equipment.

Modern printed circuit boards use alternative materials and manufacturing processes that do not involve polychlorinated biphenyls. Contemporary PCB substrates typically use materials like FR4 (flame-retardant fiberglass), polyimide, or other safe composite materials that provide excellent electrical and mechanical properties without environmental or health concerns.

When purchasing or specifying printed circuit boards today, manufacturers must comply with various environmental regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), which further ensure that harmful substances are not used in electronic components.

For applications requiring documentation of chemical composition, reputable PCB manufacturers provide material safety data sheets and compliance certificates confirming that their products do not contain prohibited substances, including polychlorinated biphenyls.

Conclusion

Printed Circuit Boards represent a fundamental technology that enables the compact, reliable electronic devices we depend on daily. From simple single-layer boards in basic applications to complex multi-layer designs in advanced systems, PCBs provide the essential foundation for modern electronics.

Understanding the different types of PCBs helps engineers and designers select appropriate solutions for specific applications, whether prioritizing cost-effectiveness, performance, or specialized requirements like flexibility or high-density component placement.

The purposes served by PCBs extend far beyond simple component mounting, encompassing electrical connectivity, signal integrity, mechanical support, and manufacturing efficiency. These multiple functions make PCBs irreplaceable in contemporary electronic design.

The distinction between Printed Circuit Boards and polychlorinated biphenyls is crucial for proper communication and specification in technical environments. Modern PCBs are manufactured using safe, environmentally compliant materials and processes that eliminate concerns about hazardous chemical content.

As technology continues advancing toward smaller, more powerful, and more efficient electronic devices, PCB technology evolves accordingly, incorporating new materials, manufacturing techniques, and design methodologies to meet ever-increasing performance demands while maintaining reliability and cost-effectiveness.